Peter Reinhart's "Epoxy method" Master whole Grain formula.

Day#1

The natural yeast leiven, and the soaker

Day #2- have all the final dough ingredients weighted and ready. Prep the ingredients for the mechanical mixing. Mix the final dough, with the goal of achieving a soft cohesive dough ball that is slightly tacky and just about passes the window pane test. Bulk fermentation until 1 1/2 times the volume is achieved.

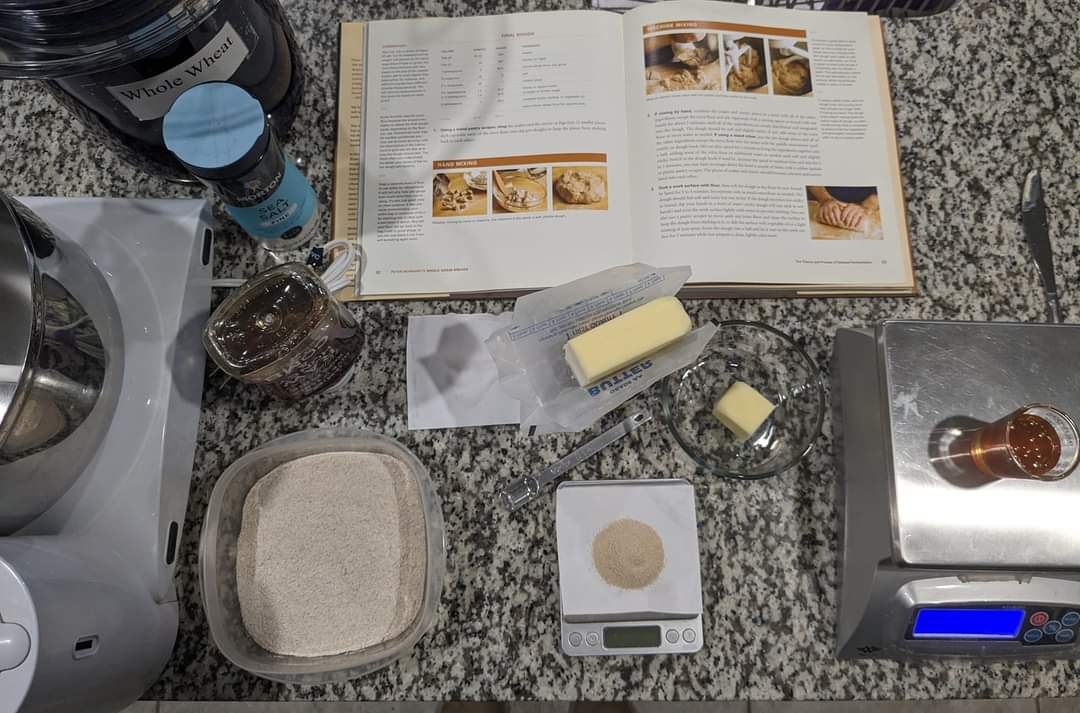

The final dough ingredients at the ready.

Final dough ingredients are prepped for the mixing

The dough after one minute at Bosch speed #1

After an additional two minutes at Bosch speed #2, the dough is very tacky. That being said, it just about passes the window pane test.

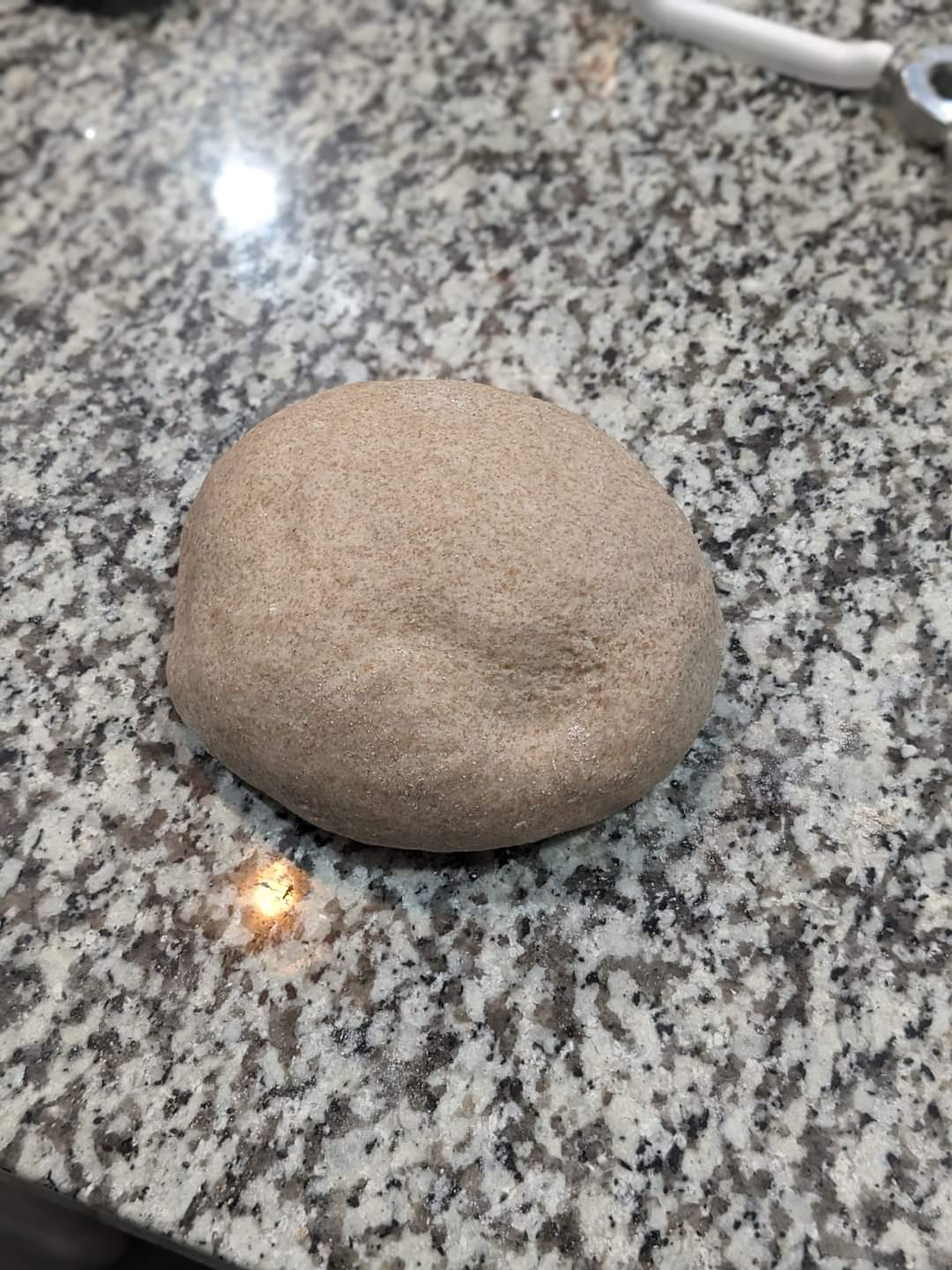

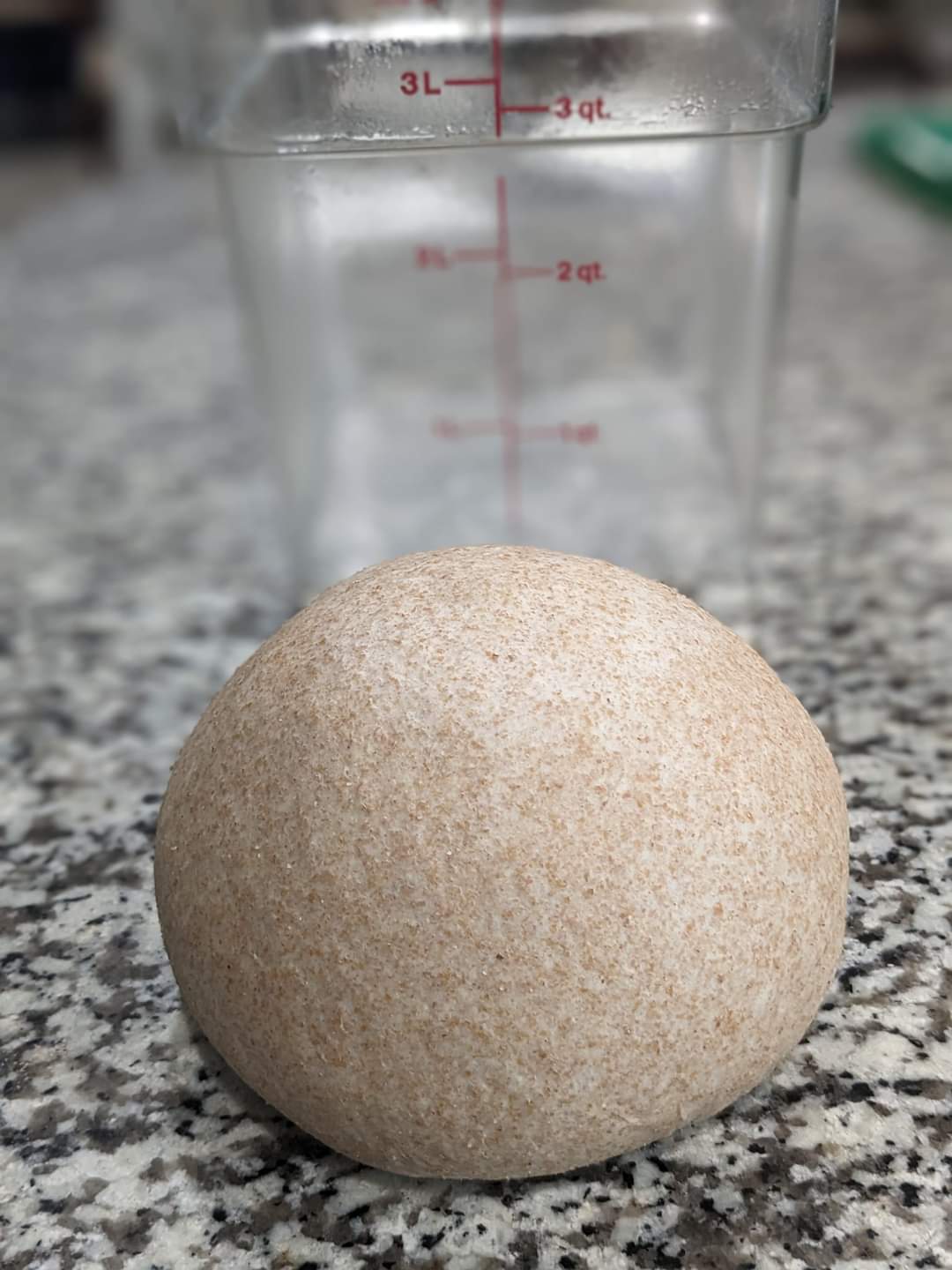

Straight out of the mixer. The dough came out clean. It required only a minimumal amount of bench flour. After just two hand kneads the dough ball is gaining strength.

After only ten or so nana style hand kneads, the dough is looking shiny, soft, and just a bit tacky.

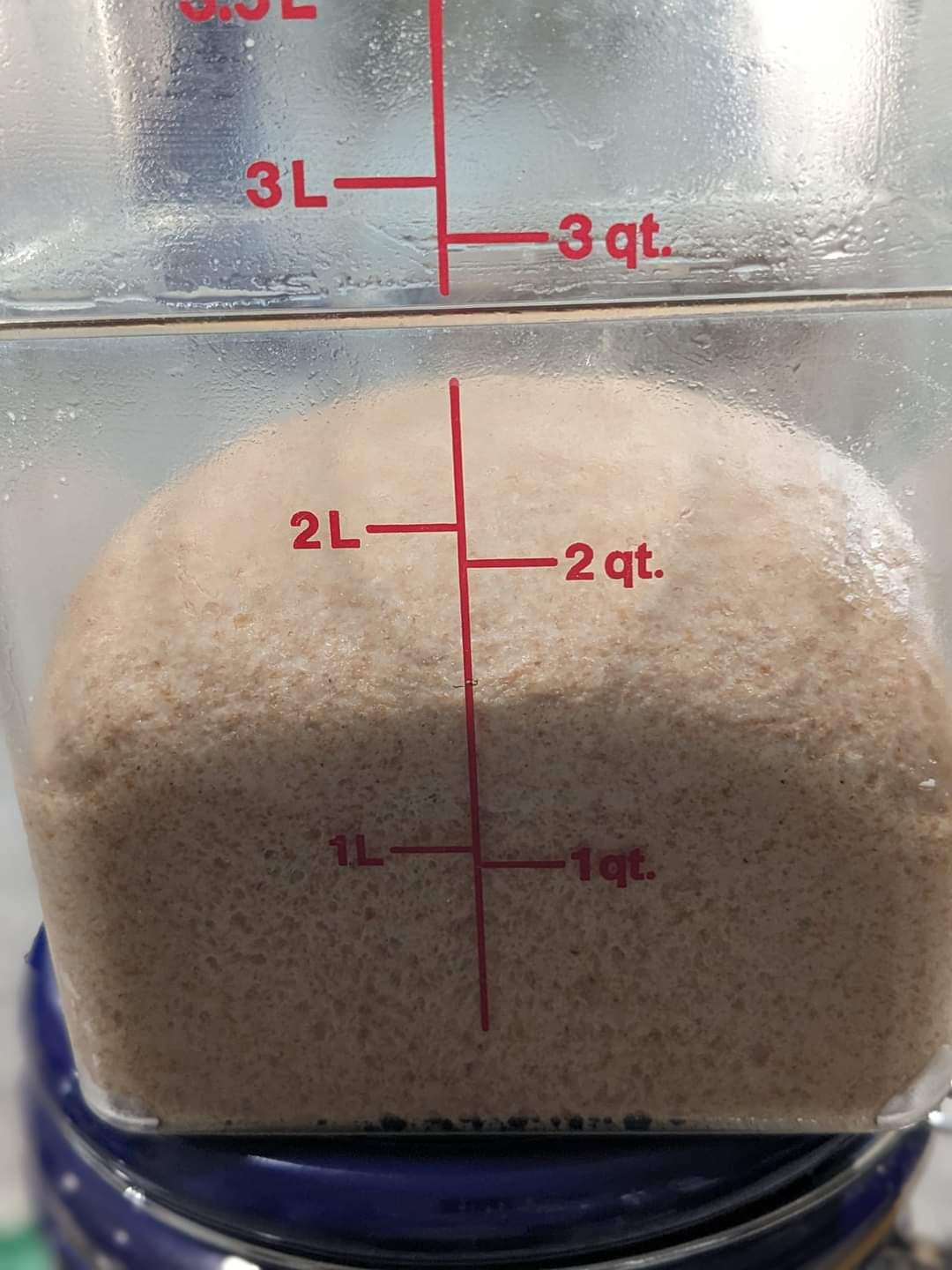

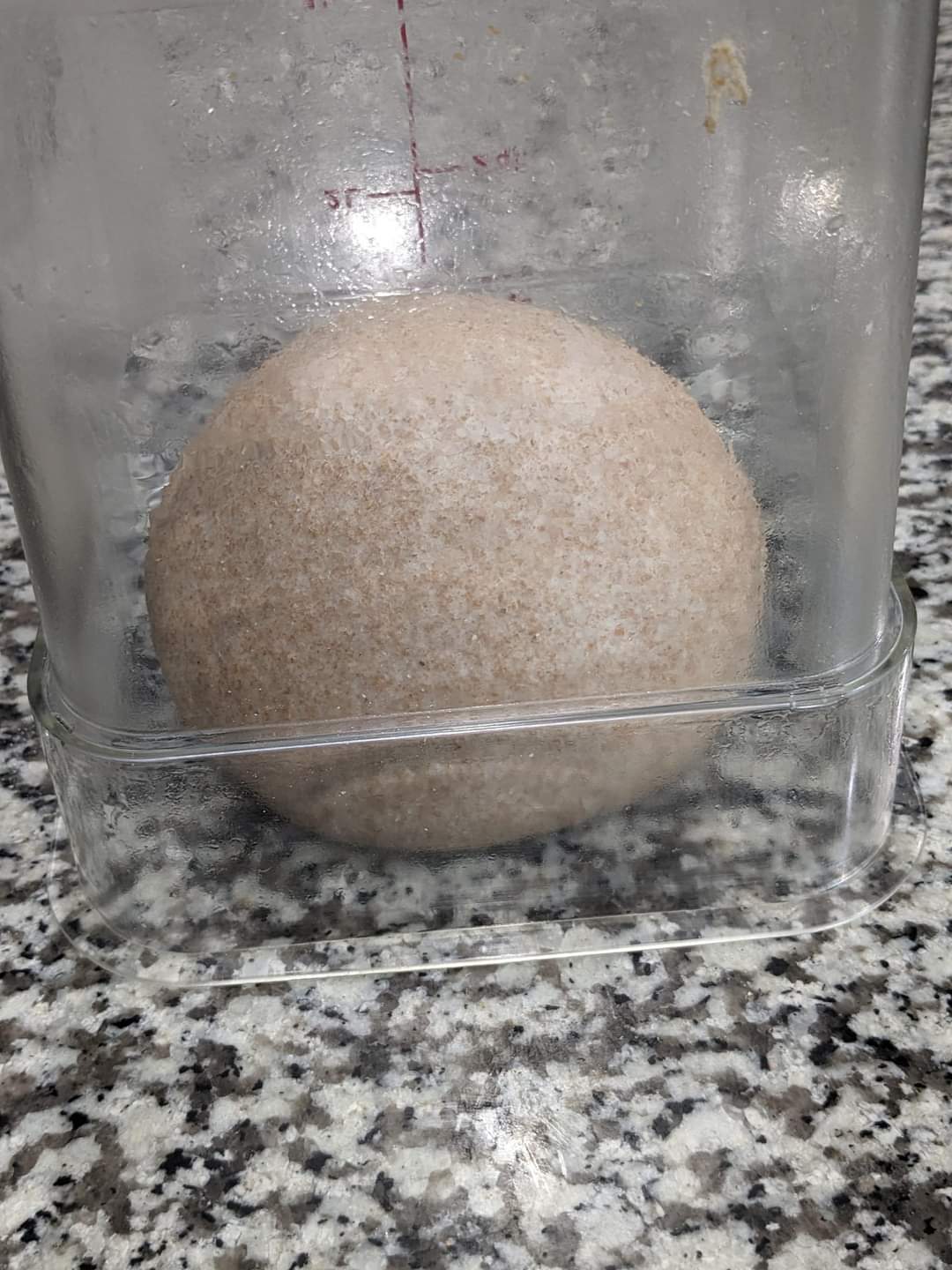

Bulk fermentation is initiated.

After 1:15 the dough ball is gaining volume. However, the target has not yet been achieved. Ambient temperature inside the fermentation container 78°F.

After a total of 1:45 the volume goal increase is achieved.

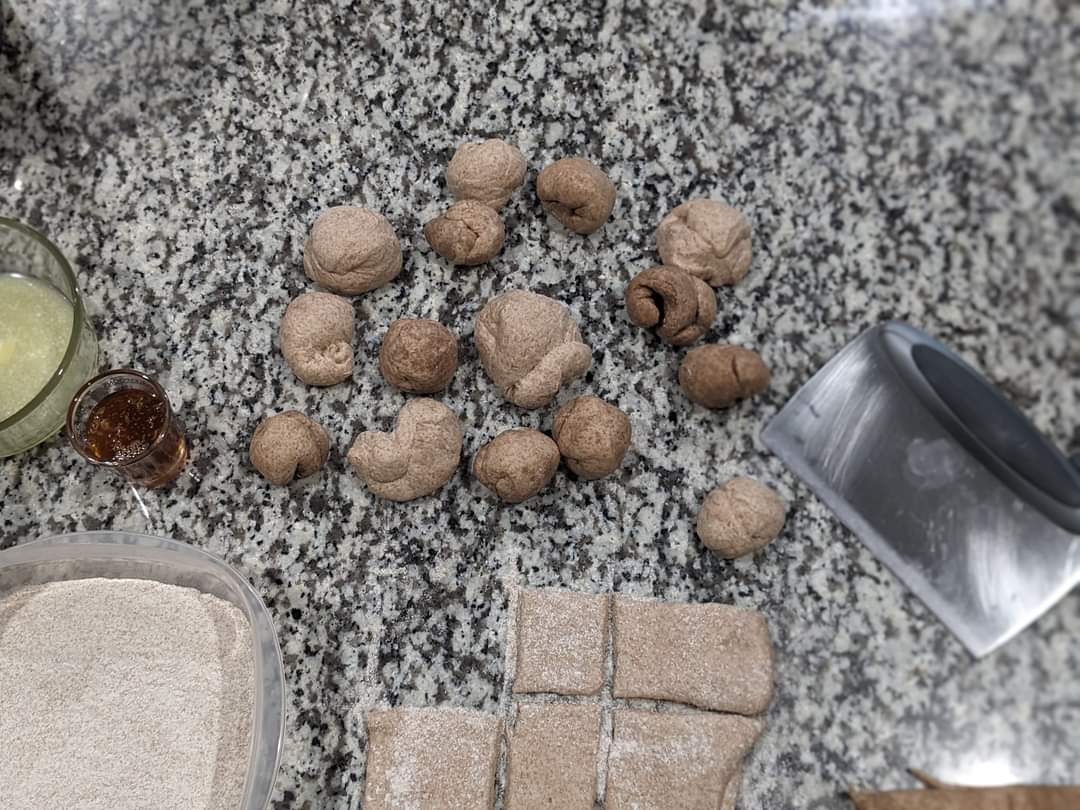

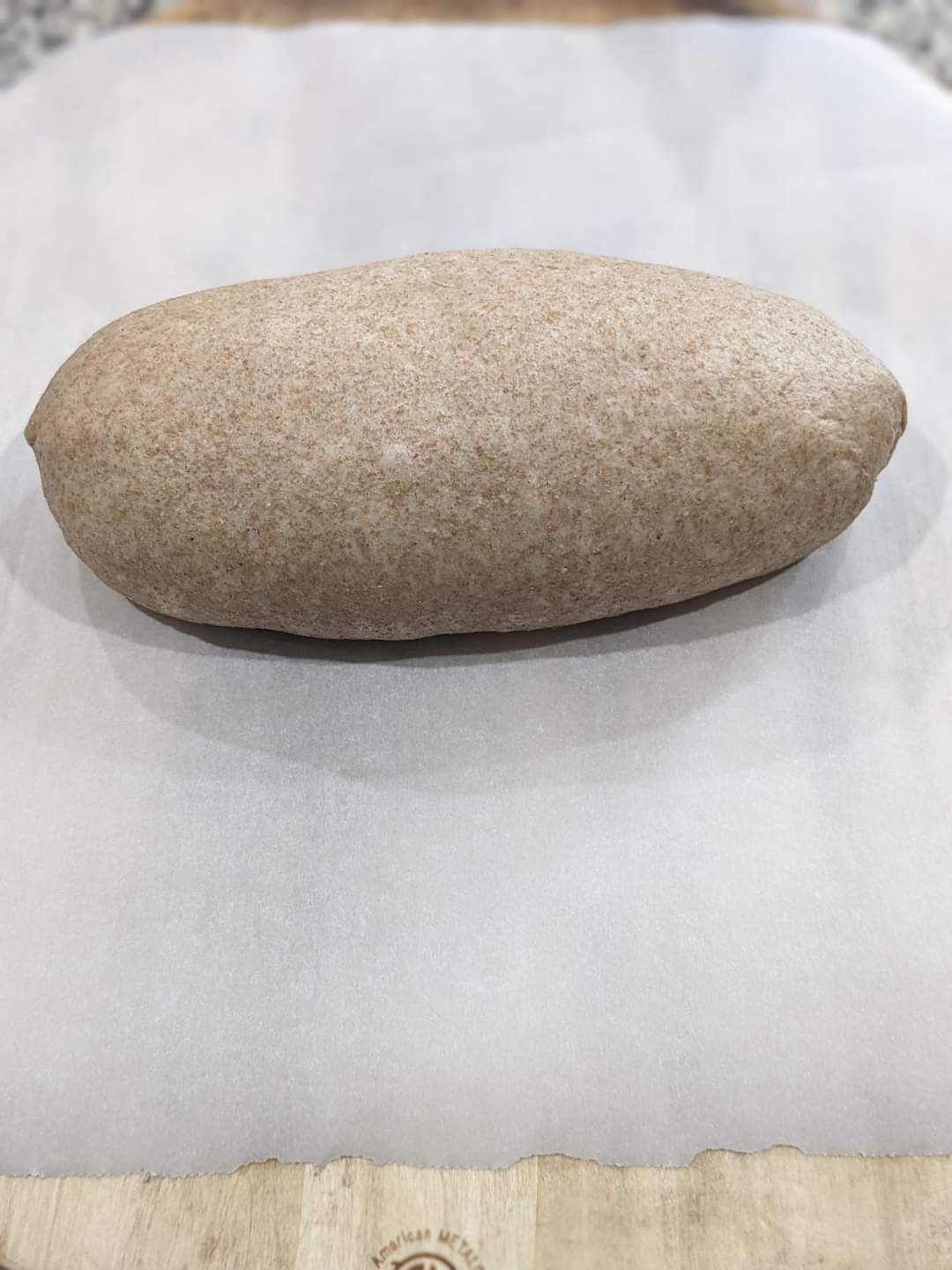

The dough ball is preshaped using bench resistance. Then a ten minute rest, before the final shaping.

The pre-shaped dough ball is shaped into a batard, with a nice tight skin. The shaped batard is put to proof. Oven, (preheat 550°F) and steaming apparatus are ready

45 minutes of proofing,and the poke test reveals a slightly under proofed batard. Moving on to the end game score, and bake.

Conclusion:

Everything about this bake is wonderful.

1. The dough was surprisingly user friendly, and easy to handle. What a pleasure.

2. For all intents and purposes no adjustments were needed during any of the stages. Out of the mixer maybe 1/2 a teaspoon of flour that made its way on to the bench was used. No extra water. No wet hands needed

3. Did I mention the oven spring? Remember, this is 100% whole wheat, with inclusions too! Amazing formula. The master formula, that only a master could develop.

3. The rich dark mahogany color is making it very hard to let this beauty cool properly. However, I will exercise restraint.

Special thanks to Mariana, a knowledgeable, excellent baker in her own rite for pointing me to a part of whole grain breads, I otherwise would have passed up. For sure I would have went straight to the formula section.

That concludes another live play by play bake. Thanks for reading.

Your friend,

Will Falzon

Comments

I discovered/invented this method while I was recipe-testing for the book in which he introduced that name, and we corresponded about it. We had each come up with it individually since it was an obvious way to get the flour to be hydrated longer. It works very well but I didn't like the effort of mixing the two parts together by hand so I rarely use it any more. Of course if you are going to use a mixer anyway that's not a consideration.

It's a very unappetizing name if you've ever smelled or mixed epoxy. But the results can be very good.

TomP

One thing I have done to make it easier to mix the two doughs is to hydrate just part of the flour, say to 100% hydration. That high a hydration is easy enough to mix in with the soaker, and you can add the rest of the raw flour afterwards. It's a reasonably decent compromise, depending on the formula.

TomP

Everything is progressing nicely!.

It looks great already!

[Later - this comment was posted when the dough was still in bulk ferment]

What a beauty! Wish I could be there when you slice it!

TomP

What whole wheat flour did you use for this, Will? I ask because one of our other members has been having WW problems, as you have probably been seeing in the general posts section of the site.

Only a few days ago I emptied the 5lb bag into the canister and threw away the sack. I have had the flour for over a month. I believe it was generic WW from Walmart.

Will F

Beautiful bread, Will! Congratulations! You have mastered it right away. 👍👍👍

Separation of the crust is due to your oven being too hot. You can preheat your baking stone, if you wish, to high temp, but the top of the bread should not bake at such high temperature. Or else you are risking all kinds of separation of the crust and tunnels and spaces under the crust. It happens even in the presliced sandwich bread we occasionally buy from large commercial bakeries.

Basically that means preheat to 550F if you wish, then ventilate the excess of heat, place bread in the oven, close the door and set your oven to 400-440F to bake.

There are some other things that could possibly cause that crust separation. Scroll down to "Holes under top crust" section here please to read about them.

Thanks, Mariana.

I will definitely, Dial down the heat. I got used to high heat quick baggette bakes to insure a good bloom. I can't wait to try the epoxy technique with other enrichments.

Kind regards,

Will F.

What exactly is the "epoxy method"? Is it mixing the firm starter with an autolyzed flour blob?

I hope it helps.

Epoxy method