Flour Milling Lab Results

I am creating a new blog entry to discuss bwraith’s flour test results just to move it up as his original entry was getting old. I admit we’re going overboard on this, but I find it all very interesting (no pictures- just discussion of flour test results) – so be warned!

Letters in my responses correspond to letters on bwraith’s test results.

I don’t know how to do that “quote thing” so I’ll just put bwraith’s original words in quotes when I want to respond to something directly.

Also, these are just my humble speculations. If anyone has a more complete knowledge, I would be most grateful to hear their interpretation of the results that were so graciously provided.

Bill,

As you said…”One main thing that was unexpected for me, was that the lowest ash white flour coming out of the second pass had high protein and wet gluten content, yet it did not have great mixing qualities in the farinograph (low mixing tolerance). My theory is that the first grinding pass may result in some very high protein dust particles being released through the 80 mesh sieve. Maybe that extra protein in the flour out of the first pass is needed for good gluten formation and is proportionately too low in the flour from the second pass. I've been reading that some of the different types of protein vary in size and whether they adhere to the starch granules or not. I guess there are milling operations that use air separation to separate the different sized protein particles and then blends them in various flours to create desired protein specifications.”

What intrigues me is that I am told that the outside of the endosperm is whiter (lower in ash) than the inside of the endosperm and although the protein/gluten is higher it is of lesser quality. If P2a was producing flour from the outside of the endosperm, this would be consistent with your result of lower tolerance. What you are getting as flour on P1 would be acting as a balance against the P2a result when blended for baking.I don’t think your process is reducing protein quality – I think that your process may be delivering different parts of the endosperm at different points in the process.Also, if you look at the Seguchi paper that I cite in my other blog post, it may be that the flour was aged insufficiently to see the full potential of its protein. He is looking at aging periods in excess of 100 days to achieve full potential.

What also intrigues me is that the results for P1 tracked so closely to whole wheat flour. I frankly would have expected those results to be more like the Golden Buffalo.Nice to know that the multi-pass milling created flour with lower starch damage than commercial flour. I have seen some discussion that some home milled flours seem to be “thirsty.” This would be indicative of a kind of starch damage that you did not experience.

Finally – when all is said and done, the values for both of the flours are within those considered acceptable for commercial baking – not necessarily ideal values, but well within tolerances. This is borne out by the bread that you produce. So, no need to age to maximum potential to get good bread.I know, I need to get enough flour milled to get some tests on my stuff. I’ll do it – I really will. I have some other things to attend to in the short term, but I know I’ll do it. In the meantime –

Happy Milling!

Pat

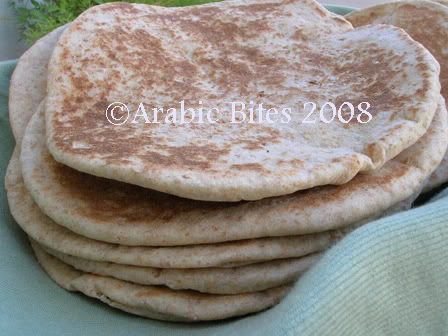

pan dulce

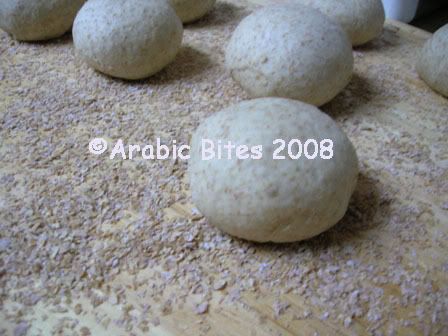

pan dulce  dough balls

dough balls  proofed and slashed balls

proofed and slashed balls Baked pan dulce

Baked pan dulce  pan dulce crumb

pan dulce crumb

3

3 Seeded Cracker Animals321

Seeded Cracker Animals321